| Preparing

the Shell The

first task was to strip off all factory fitted parts leaving just the basic shell

structure. This entailed removing

- the 48" fans

- the radiator

grilles

- the air intake

grilles

- the primer coat of

paint

so that I was left with a shell which

was as good as 'virginal' |

|

And so to work .....

This GP9 has four 36" fans

instead of the two 48", so to alter the shell to accept them it was first

necessary to plug up the 48" holes. I made two 'plugs' of .060" styrene

sheet and sanded them to a snug fit to the holes and fixed them in place with Microscale

Micro Weld. I have found that not all plastic solvents are suitable for affixing

styrene to P2K shells but Micro Weld works well. I had originally used another

solvent which has served me well in the past but it did fail later on in the process when

I was cutting the holes for the 36" fans. After re-affixing with Micro Weld the

shell withstood the rigours of sawing and paring and sanding.

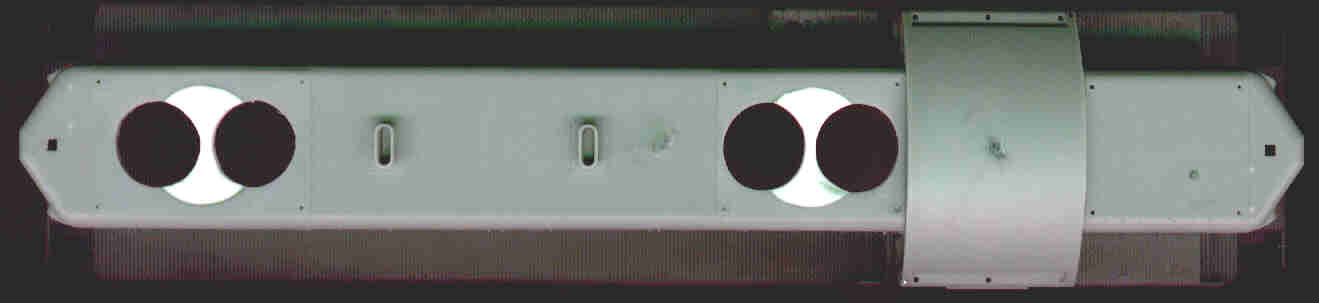

The

scan shows the styrene plugs fitted but the edges not yet filled and sanded smooth |

|

When I offered the Detail Associates

'chicken wire' style grilles up to the shell I found that there was insufficient overlap

to ensure a strong bond. I think these parts were intended to be used with the

original GP18 shutters but I found that the locating pins moulded on the back were not

long enough to properly engage the shutter mouldings and that these, being made of

an acetal plastic, would not readily glue to the chicken wire grilles. I opted to

omit the acetal shutters and to fit .020" x .050" strips of styrene around the

perimeters of the shutter apertures to provide a suitable edge to which to glue the

chicken wire grilles. A test fit told me that it would not be evident that there are

no shutters behind the grilles.

The

scan shows the strips of styrene (blue) fitted ready to receive the grilles |

|

I choose to use Detail Associates

very fine brass nbw castings for handgrab bolts. These require a smaller mounting

hole than the P2K plastic parts. I opened out the moulded in holes in the shell,

on top, on the ends, on engineer's side of the long hood, cab sides, pilots

and steps, to .020" with a jeweller's broach, inserted Evergreen styrene

.020" rod leaving it a little proud of the surface, and fixed with solvent.

When dry I went around the shell with the PBL sprue nippers and snipped off the excess

leaving a surface that requires just a tiny touch with 600 grit wet and dry paper to

complete.

The Evergreen rod is white which

provides a handy contrast to the grey plastic of the shell and a good guide as to where

the holes need to be drilled for the DA nbw castings.

At this stage I filled the flaws in

the joins on hood top plugs with Squadron Green putty. I know this product is not

'flavour of the month' with some modellers due to reported shrinkage and crumbling with

age. I have not experienced this, possibly due to my using it only for repair

of small cracks and flaws. My technique has been to significantly overfill and allow

the putty to harden completely before paring off the excess and finishing off with 600 and

1200 grit wet and dry paper. I also applied putty to the moulding gate flaws in the

tops of the hood and the cab roof and filled the horn mounting hole on top of the short

hood because 5623 carries her horn on the cab roof.

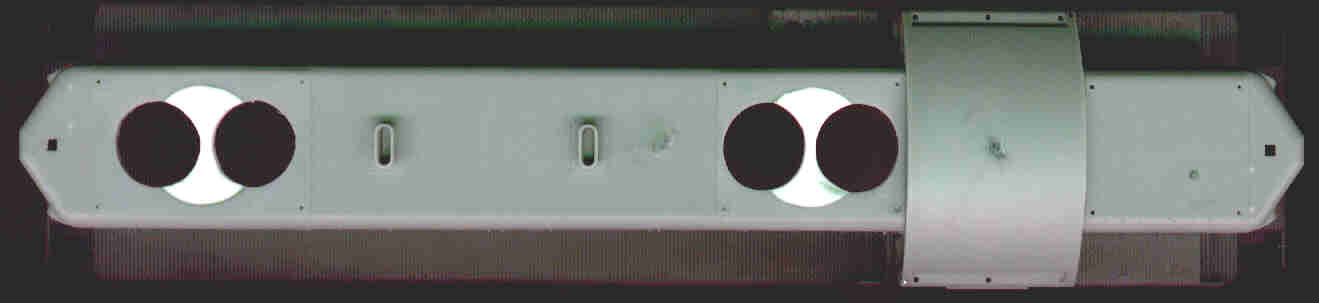

| The

extent of generous filling of flaws with 'Squadron Green' putty . . . . |

|

. . . . and all that remains after scraping and sanding and

cutting holes for 36" fans. . There are distortions in this scan. The spacing

of the fans is the same each end and the holes are smooth and round |

|

The side sills:

The side sills were modified to full depth by the addition of

Evergreen strip styrene .060" thick and then sanded down to match the depth of the

short full depth section of the P2K sill. After this photo was taken the sill slots

were drilled and cut and 2.5 mm holes drilled for the water and fuel fillers. |

|

Headlights:

I removed the cast on headlights

because I want to use integrated castings of the SP light package.

Number Board Access Hatches:

Howard Wise was so kind as to whip

out his tape measure and give me exact sizes for these hatches which are 11.25" high

by 27.5 inches wide - or 3.28 mm x 8.02 mm in H0 scale. I am going to cannibalise

some Cannon doors to make the hatch doors. I have been unwilling to physically mark

the shell in preparation for cutting out the hatch apertures - I have had misadventures

with scribers in the past!

So I have opted to mark out my aperture placement with masking

tape. This has enabled me to play around with the positions until I have them where

I want them; gives me clear lines to which to cut; and protects the

immediately surrounding area in the process....

... and the end result.

Clean apertures and no scarring of the surrounding shell. Phew!

The cast on class lights

have been pared off and drilled to accept MV lenses.

|

|

|

Final touches to prepare the shell:

I decided not to use the supplied acetal sun shades due my

inability to get the mouldings to fit seamlessly in the slots in the roof. I filled

the slots with styrene strip and smoothed off the roofline. Whilst at it I filled

the holes in the roof top where the door hinge pins are exposed. |

|

What about the louvres?

There are some minor inaccuracies in

the louvre configuration due to my using a GP18 shell for a GP9. On the side

of the tool box (or battery box?) below the short hood there are two groups of three short

louvres. For 5623 these should be two groups of six short louvres. On

the fireman's side of the short hood there should be two groups of (four?) short louvres.

After weighing up how I might add these louvres, including casting some in

resin and gluing them to the shell I have decided to leave well alone rather than risk

damaging the shell.

Return

to main page