Wiring and Lighting Issues

My aim was to produce a model that

runs reliably with directional constant lighting and simulated gyralights.

Close examination of the construction

of the trucks showed that electrical continuity on the model as purchased relies

upon

|

|

the

weight of the frame bearing on the top of a bare metal pivot plate on each truck, and |

|

|

a

riveted joint between the pivot plate and the bare metal truck frame which supports the

wheel bearings. This riveted joint was loose enough to allow the truck to pivot in

an end for end manner |

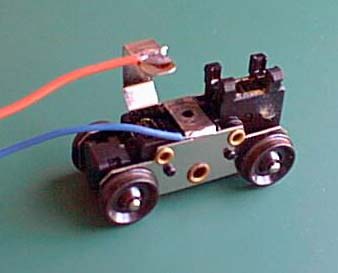

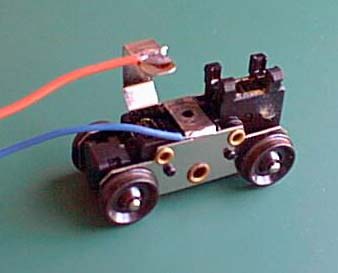

| The model as

purchased was running smoothly. The two weaknesses I have identified may be more perceived

than real, nevertheless I decided to 'hard wire' the trucks to minimise the

development of any future continuity problems. I did so by soldering hookup wire to

the joint between the pivot plate and the truck side members as indicted by the blue wire

in the accompanying photo. |

|

Lighting

I have been tossing

around ideas about constant lighting. In some discussions I have detected a swing

back to lighting modules in parallel with motors rather than fed from diodes in series

with motors. Some modellers are concerned about the loss of the first 2.1 volts to

the motor when three diodes are used in each direction - two to provide the voltage of

1.4v for the bulbs and one to permit the lights to be directional. I prefer the idea

of reserving some voltage for lighting in this manner rather than have the motor begin to

turn before the lights come on.

For lighting I have

chosen Mitey Lites by Circuitron. They are 1.5v high output and are tiny enough to

fit in 1.5mm holes in the shell or light castings. I am using eight such bulbs.

2 for the headlights at each end and two for the gyralights at each end.

Each pair of headlights

will be fed off a pair of diodes in series with the motor with a third diode to determine

direction.

I have experimented with

a circuit to provide directional high-low brilliance to simulate the gyralights and I have

included the circuit diagrams on links below. I can't claim too much originality.

These circuits are a cobbling together of bits 'n' pieces from other circuits I

have found published in data sheets and on the web.

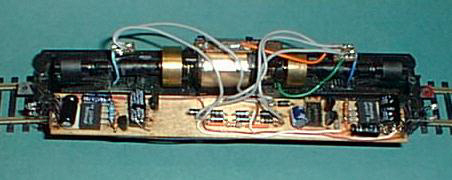

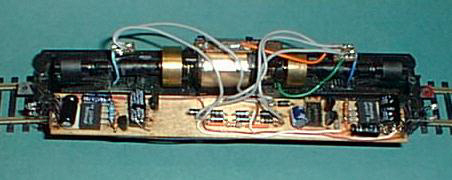

I have mounted the the

directional constant lighting diodes and the two gyralight simulation modules (one for

each end as I want them to be directional as well) on a strip of .040" three ply on

which I have 'breadboarded' the components. It was intended to be experimental so

that a PC board could be drawn up from the bread board layout, but it is working

just fine as it is and I see little point in disturbing it even though it looks a bit

'Heath Robinson'.

This photo was taken

when I had the bulbs mounted on the circuit board. In fact they proved to be too

fragile to be placed into the bulb holders with tweezers when the circuit board was

mounted in the shell and I lost about ten of them over several sessions of fitting and

removal of the board. I have now mounted the bulbs (there are eight of them) in the

shell with their leads being soldered to small pc boards epoxied to the inside of the hood

ends and with small jumper wires soldered between these pc boards and the main circuit

board. It means a soldering job to remove the circuit board, but it should not

often be necessary.

You will note that I

have discarded the cast ballast weight. Some sheet lead will be glued to the inside

of the shell to compensate for some of this lost weight.

The two circuit diagrams

may be accessed from the links in the following paragraph:

The underlying Directional Constant Lighting circuit is well known but there are a

couple of extra features. The diagram shows how the Gyralight

Modules interface with the basic circuit to provide directional gyralight

operation. This requires two complete modules to be built and the extent of the

circuitry for each can be gauged from the photo above which has a module at each end of

the circuit board. There is also a 1K resistor across the 2 sets of three diodes

that make up the directional constant lighting part of the circuit. I use a feedback

controller which relies on being able to detect a back EMF signal from the motor and the

diodes prevent that current from being detected. This resistor provides a bypass for

the back EMF signal without adversely affecting the operation of the lighting

circuit.

A few pointers about the

circuits:

The dimness of the

'off cycle' of the gyralights is determined by the resistor between the collector and base

of the 2N3906. I have found the 22R to look right to me. Increasing this value

will further dim the light. Reducing the value will brighten the light.

Leaving the resistor out altogether results in a complete on/off flashing - but there are

cheaper ways to do that!

The regular bright

flash that simulates gyration will be dulled if there is not 1.6 to 1.7 volts at the

output of the LM317. In one of my modules the specified value of 68R produced 1.7

volts but in the other it did not and I had to substitute a value of 75R to produce that

voltage. The circuit is clearly sensitive to tolerances in the manufacture of the

components used and a little experimentation may be necessary to achieve the result you

want.

Similarly I had to

substitute a capacitor. The value of 270 mfd between pins 2 and 8 of the LM3909 IC

produced 'gyrations' at 55 per minute in one module. In the other I had to

substitute 330 mfd to achieve the same rate.

The LM3909 is now

obsolete but may still be found in some electronics stores. A pin for pin compatible

IC, NTE876 is thought to be a direct substitute, but I have not tried one yet.

The voltage regulator

part of the circuit specifies a 25v 220 mfd capacitor. The only ones I had (or found

at the local electronics shop) were unacceptably large. I had some small 16 volt

jobs though and have used them. I can't imagine that I will exceed the 16 volt

rating but if I suffer an internal explosion I'll know that I have been pushing the

limits! The remaining capacitors are all in the low voltage part of the

circuit and I have used 3.3 volt and 5 volt capacitors simply because I had them on hand

from a wrecked VCR.

A hard lesson learned

Had I known that the

fitting of lighting would have involved so much handling of the shell I would have sorted

it out much sooner in the building process. I now have a shell with some rather

battered detail parts and more paint chips and abrasions than I can call weathering so I

have some patching up to do. Once that is done, the loco will be finished and

I'll see if I can make a short AVI file of the gyralights. It will hinge on my

ability to get an adequately sharp focus on my older technology digital camera which can

record a brief series of AVI frames. If it works, you'll see it here.

Return

to main page